What is Lithography?

Lithography is a printing technique that has been widely used for centuries, combining chemistry and artistry to create high-quality prints. It is based on the principle that oil and water do not mix, allowing images to be transferred from a specially prepared surface onto paper or other materials.

Originally developed in the late 18th century, lithography revolutionized the printing industry and remains relevant today, both in traditional printmaking and advanced semiconductor manufacturing. This article explores the lithographic process, its types, and key applications.

What is Lithography? A Historical Perspective

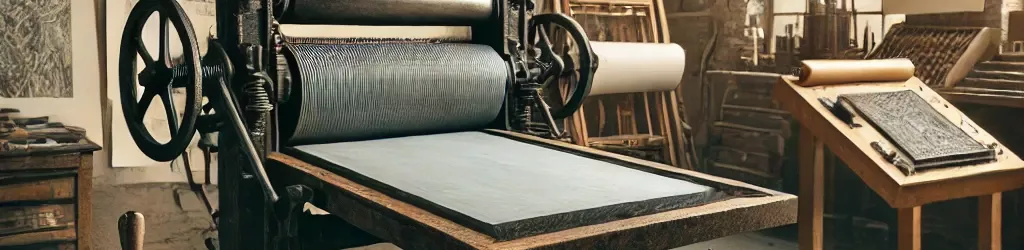

Lithography is a printing technique that revolutionized the printing industry, making it possible to produce high-quality prints quickly and affordably. The word "lithography" comes from the Greek words lithos (stone) and grapho (to write), meaning "writing on stone." The process was first developed in the late 18th century by German playwright and actor Alois Senefelder in 1796. Senefelder, initially seeking a way to cheaply print his own plays, stumbled upon the idea of using a stone surface to create prints.

Unlike earlier methods such as woodblock or copperplate printing, lithography allowed for more detailed and intricate designs. It was a significant breakthrough because the process involved drawing directly onto a flat surface, making it easier to reproduce images and text without the complex engraving techniques required in previous methods. This made lithography not only faster and cheaper but also more versatile for different artistic and commercial uses, such as affordable magazine printing.

By the 19th century, lithography had spread rapidly and was used extensively in the production of books, posters, maps, and later even money. It quickly became a preferred method for artists and illustrators, enabling them to reproduce their artwork in large quantities. Lithographic printing also played a vital role in the advertising industry, as businesses sought colorful and vibrant prints to capture consumers' attention.

Today, lithography remains a dominant method of printing, particularly for large runs of books, magazines, and promotional materials. It is also widely used in fine art printmaking, allowing artists to produce works with rich colors and sharp detail. The process, which began as a simple idea to print plays, has evolved into one of the most influential and widely used printing methods in the world.

| 1796 | Invention of Lithography by Alois Senefelder | Alois Senefelder invents lithography as a method for printing plays, using a stone surface for creating prints. |

| 1800s | Spread to Commercial Printing | Lithography becomes widely adopted for commercial printing, including the production of books, posters, and maps. |

| 1830s | Lithography in Fine Art | Artists begin using lithography as a medium for producing high-quality prints, making it a significant tool in the art world. |

| 19th Century | Development of Color Lithography | The introduction of color lithography allows for more vibrant prints, contributing to its role in advertising and book illustration. |

| 20th Century | Modern Lithographic Printing | Lithography evolves into offset printing, which becomes the dominant method for high-volume printing in commercial industries. |

As time passed, lithography evolved from a manual process to the modern offset printing technology we use today. With its ability to produce large volumes of high-quality prints quickly, lithography has become indispensable in industries ranging from publishing to advertising, and even in the production of fine art prints. The development of lithography paved the way for many other printing technologies, influencing the way we communicate and share information worldwide.

Types of Lithography

Lithography is a versatile printing technique that can be adapted to different materials, printing methods, and industrial applications. Over time, various types of lithography have developed, each suited for specific tasks. Here are some of the main types:

- Traditional Lithography (Stone Lithography): This is the original form of lithography, invented by Alois Senefelder in 1796. It involves drawing or painting an image directly onto a stone surface with an oily medium, such as a grease pencil. The stone is then chemically treated to allow ink to adhere only to the drawn areas, while the rest of the surface remains ink-repellent. This method is still used in fine art printmaking today.

- Offset Lithography: Offset lithography is the most common form of commercial printing. It involves transferring inked images from a lithographic plate to a rubber blanket and then onto the printing surface, typically paper. This technique is widely used in high-volume printing for newspapers, magazines, brochures, and posters. The offset process allows for sharp, high-quality prints at a relatively low cost per unit.

- Photolithography: Photolithography is primarily used in the semiconductor industry. This technique involves using light to transfer patterns onto a photosensitive material, which is then chemically developed. Photolithography allows for the creation of extremely detailed patterns, necessary for the production of microchips and other electronic components. It plays a crucial role in the manufacturing of modern electronics.

- Planographic Lithography: Planographic lithography is a method where the printing surface remains flat, as opposed to being raised or etched. It is mainly used for printing high-quality images and is similar to offset lithography but without the need for a rubber blanket. This method is often used in fine art printmaking and for high-end commercial prints.

Each type of lithography serves a unique purpose. While traditional lithography is popular in art, offset lithography excels in mass-production printing. Photolithography is critical in electronics manufacturing, and planographic lithography is favored for high-quality art prints. Understanding these different types allows businesses and artists to choose the best method for their specific needs.

The Lithographic Process

The lithographic process is a highly sophisticated technique that involves several stages to produce a print. Understanding each step helps to appreciate the level of detail and precision required. This process is commonly used for high-quality prints, such as catalogs, where vibrant images and clear reproductions are essential.

Here’s a step-by-step breakdown of the lithographic process:

- Preparing the Plate: The first step in the lithographic process involves preparing a smooth, flat surface, traditionally a stone or metal plate. This plate is coated with a light-sensitive emulsion. The plate is then either hand-drawn or photographed with the image that needs to be printed. In the case of modern offset lithography, the image is transferred to a metal plate.

- Image Creation: The image is created using a greasy substance, such as a lithographic crayon or ink. This image will attract ink, while the non-image areas will repel it. This stage is especially important in printing detailed images like those seen in catalogs, where accurate reproduction of products or artwork is crucial.

- Chemical Treatment: Once the image is created, the plate undergoes a chemical treatment. This treatment ensures that the areas that are not part of the image remain water-repellent, while the image areas are ink-receptive. This step is essential to the lithographic process and ensures the clarity and quality of the final print.

- Inking the Plate: The plate is then inked using special rollers that apply the ink to the image areas. The inked image is now ready to be transferred. The ink used in lithography is typically oil-based, which makes it adhere to the greasy areas of the plate. This is particularly important when producing high-quality prints, such as those required for catalogs, where sharp, clear imagery is needed.

- Transferring the Image: The final step involves transferring the inked image from the plate to the printing surface (usually paper). In offset lithography, the image is first transferred to a rubber blanket before it is applied to the paper. This method reduces wear on the plate and allows for higher print quality, which is especially important for projects requiring detailed reproduction, like catalogs.

The lithographic process produces high-quality prints, making it an ideal choice for catalog printing and other commercial applications that demand fine detail and color accuracy. Lithography's ability to produce multiple copies quickly and with consistent quality has made it a go-to method for large-scale printing projects.

Modern Lithography: Applications and Advantages

Modern lithography has come a long way since its invention in the late 18th century. Today, it is one of the most widely used printing techniques, especially in high-volume commercial printing. Lithography's ability to produce consistent, high-quality prints quickly and efficiently has made it the go-to method for a variety of applications, including books, magazines, newspapers, catalogs, and promotional materials.

One of the key advantages of lithographic printing is its versatility. Lithography can be used to print on a wide range of materials, including paper, plastic, metal, and even textiles. This makes it ideal for a variety of industries, from publishing to packaging. Additionally, the high-quality results achieved with lithographic printing are unmatched by other methods, making it the preferred choice for producing vibrant images, sharp text, and fine details.

Another major advantage of lithography is its cost-effectiveness in large print runs. Once the plates are created, the cost per unit decreases significantly as the quantity increases, making it highly efficient for mass production. This is why lithography remains a popular choice for printing large quantities of items such as catalogs, brochures, advertisements, and even custom calendars. The precision of lithography ensures that each page of a custom calendar is printed with vibrant colors and sharp images, making it ideal for creating visually appealing and professional-looking calendars tailored to specific needs.

The advent of modern offset printing technology has further improved the efficiency and precision of lithographic printing. Offset printing, which uses a rubber blanket to transfer ink from the plate to the printing surface, has made it easier to produce high-quality prints at a faster pace, with greater color accuracy and less ink wastage.

Today, lithography continues to evolve with the integration of digital technologies. Digital lithographic printing allows for even faster turnaround times and greater customization options. As technology advances, lithography is expected to remain a key player in the world of printing, offering unmatched quality, speed, and flexibility for both commercial and artistic applications.

Frequently Asked Questions

What is lithography?

Lithography is a printing process that relies on the principle that oil and water do not mix. It involves creating an image on a flat surface, usually a stone or metal plate, and transferring it onto paper or another material. Lithography is known for its ability to produce high-quality prints with sharp images and vibrant colors.

What are the advantages of lithography?

Lithography offers several advantages, including high-quality print results, fast production speeds, and cost-effectiveness for large print runs. The process allows for accurate color reproduction, making it ideal for printing items such as magazines, books, catalogs, posters, and even custom calendars. Additionally, lithography can be used to print on various materials, including paper, plastic, metal, and textiles, adding to its versatility.

How does the lithography printing process work?

In lithography, an image is first drawn onto a flat surface, typically a metal or stone plate, using oil-based ink. The non-image areas of the plate are then treated to attract water, while the inked areas repel it. During the printing process, the plate is dampened with water, then inked. The ink adheres only to the image areas, which are transferred to paper through a press, producing the final print.

What is the difference between lithography and offset printing?

While both lithography and offset printing rely on the same basic principles, the key difference lies in the method of transferring ink. In offset printing, a rubber blanket is used to transfer the ink from the plate to the printing surface, which allows for smoother printing on a variety of materials. Lithography, on the other hand, typically uses direct contact between the plate and the paper.

Can lithography be used for custom printing projects?

Yes, lithography is highly versatile and ideal for custom printing projects. Whether it's custom calendars, personalized brochures, or unique artwork, lithographic printing offers the flexibility to produce high-quality prints tailored to specific needs. The precision and color accuracy make it especially popular for projects that require vibrant images and fine details.