A Complete Guide To Digital Printing For Textiles

In the 1980s, the garment sector began the all-over textile printing movement. Later, flatbed and rotary screen printing became more widespread, even though roller printing was initially the predominant printer technique.

People’s interests, preferences, and requirements become increasingly different with each passing era. The fashion industry and the younger generation in today’s culture are especially fashion-conscious regarding their attire. Because of this, the demand for textile printing that covers the entire surface is steadily growing in countries worldwide.

Many more products, such as t-shirts, shirts, jeans, three-piece sets, bed sheets, or any fabric, use rotary screen printing. The methods of textile printing in the textile industry come with several restrictions, one of which is that not all sorts of designs can be produced using flatbed or rotary screen printing methods.

This is just one of the restrictions. Even though textile printing techniques make it feasible to print in anywhere from 1 to 20 colors, in most cases, less than 12 colors are used for textile printing due to the following two factors:

1) The expense of the print job

2) The difficulty of using the machine

Screen printing processes also do not allow for clear highlighting of photo prints or the effect of three-dimensional printing. The textile printing industry has been given a new chapter, digital textile printing, to address and solve these different challenges.

What Is Digital Textile Printing?

If you have no idea what digital fabric printing was when you first started, here is the answer to your question:

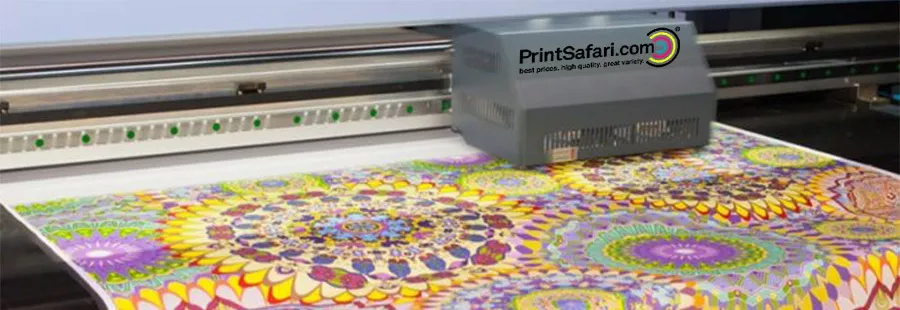

Digital fabric printing is putting colorful patterns and designs onto fabric using a printing press. During the fabric printing process, one or more colors are applied to the fabric in certain areas only and in patterns that are very clearly defined.

When a fabric is printed correctly, the colors are bonded to the fibers, making it resistant to wear and tear caused by factors such as washing and rubbing. Now you may wonder if a dye is the same as printing. The dying process is comparable to the printing process.

However, the entire fabric is saturated with a single color in the dying process. In contrast, repeat patterns are printed all over the fabric or on certain parts in the printing technique.

Types of Digital Printing of Textiles

Several applications exist for printed textiles. Digital textile printing can be done in several methods, not just one. Following are a few types of textile printing:

1. Solid ink

Solid ink is more frequently used for larger-scale printing projects, like those undertaken by graphic designers. Waxy resin-polymer is used in solid ink printing to produce eye-catching advertisements and durable pictures.

2. Laser and inkjet technology

The two most popular types of digital printing are inkjet and laser. Digital inkjet printers and laser technology are widely used in offices and private residences. The present market includes various newly developed DTP technologies that have been introduced.

Thermal inkjet, piezoelectric inkjet, continuous inkjet, thermal transfer, electrostatic, and electrophotography are some of the new innovations, and each has its own set of traits, benefits, and limits.

3. Dye sublimation

Heat transfers and sublimation ink in digital textile printing can imprint images on various materials for clothing, accessories, and other products. The most common printing technique for a custom garment is sublimation, and a blank garment is ideal for your digital print.

4. Digital press

Digital presses are fantastic for high-volume orders like booklets, brochures, labels, and business cards.

Types of Digital Textile Printers

Digital textile printing equipment prints designs directly onto fabric rolls, unlike “direct-to-garment” printers, which embellish already-made clothing items. These fabric rolls are then cut and sewed into a range of products.

Depending on the type of fabric, a single roll of printed fabric could be used to make various styles and sizes or even the repeat size of shirts, dresses, garments, shorts, and fashion accessories.

They can also be used in home textiles to make the repeat size of pillowcases, sheets, tablecloths, duvets, upholstery, or drapes. Shirts, dresses, slacks, and shorts could also be made from the same fabric roll.

Single-pass inkjet printer

Single-pass inkjet printers span the width of the substrate. These digital printers produce textiles in a single pass. As the substrate of the single-pass printer moves in front of the stationary printheads, a single pass is required to apply all of the ink onto the fabric.

Digital textile printing may take place at rates of up to 295 linear feet per minute using a single pass printer, one of the promising developments of the textile printing industry.

Multi-pass inkjet printer

Multi-pass industrial printers use groups of moving print heads that “scan” the breadth of the fabrics back and forth. Durst, EFI, Epson, Mimaki, Mutoh, SGPrints, DGI, and Kornit Digital, are manufacturers of multi-pass printers.

Single-Pass Textile Printing VS. Multi-Pass Textile Printing

Advantages and disadvantages of multi-pass digital textile printing

Multi-Pass digital textile printing is not cost-effective compared to single-pass digital textile printing, as well as the ongoing costs of maintaining the digital textile printing technology.

The ink for the print head of multi-pass digital textile printing is often more easily accessible and available at a lower cost than the ink used for single-pass digital textile printing printheads.

Since the printhead makes many passes, if one of the printheads were to fail, the inconsistency in print would be corrected the next time the printhead made its pass while performing the printing process on the textile.

Multi-pass digital textile printing may not be for you if you need prints produced at high speed and high resolution. The printhead must repeatedly pass over the substrate to produce the desired picture.

The printing quality of the printed textiles is another factor to consider while using multi-pass digital textile printing. The color separation could get muddy from the repeated inks, losing the crisp print quality many people want from traditional printing.

Additionally, the time of dry heat could be needed because of the ink’s potential for smearing when the paper flexes under the weight of the printed ink layers. Overall, while selecting which is ideal for your company, you should consider the time required for multi-pass digital textile printing.

Advantages and disadvantages of single-pass digital textile printing

The expensive initial investment required for many printheads is the most significant disadvantage of single-pass digital textile printing and screen engraving, even though single-pass digital printing produces prints of high quality and sharpness.

The upfront expense of the printer heads required for single-pass digital printing may be a barrier to entry for businesses attempting to transition away from multi-pass printers and onto the more current digital printing technology.

When it comes to cleaning the printheads of the printer in the textile industry, using more than one printhead at a time increases the risk of one of them getting clogged.

If the printhead is clogged or isn’t oriented correctly, you could see white streaks across your prints and tiny droplets. This can also happen if the printhead is dirty.

Which one to choose?

When deciding on a way of digital printing to use on textiles, there are a few things that you need to ask yourself. The first question to be asked is how large of a volume you want to produce with the new printing method. Printing in multi-passes is the most efficient method for your manufacturing procedure if you print between 0.5 and 1.5 million meters per year.

Do you wish to print anywhere from 4 million to 20 million meters yearly? If you want to produce large numbers of textiles quickly, printing with a single-pass printer might help you achieve the needed pace.

When choosing between different digital textile printing forms, the amount of money you are willing to spend on a new printing method is an additional crucial consideration.

Because printing in a single pass takes a significant financial commitment, asking yourself these questions will help you determine whether or not printing in a single pass is even a possibility for your business.

What are Pre-Treatments and Post-Treatments?

In the screen printing textile industry, fabrics need to be cleaned and pre-treated before they can be printed, compared to traditional printing.

The pre-treatments help to bond the dye in ink to the fibers in the textile, regulate the distribution of ink droplets, maximize the intensity of the colors, and promote ink absorption for quicker dry periods. All of these benefits come from the ink itself.

Textile printing techniques say that to prevent the ink from rubbing off or being washed away, the material must be dried or coated once it has absorbed the ink. There is a lot of screen-printed fabric that needs to be washed to remove any ink residue.

In-line systems have been created by companies such as EFI, Durst, and Kornit to handle all of the pre-treat and post-treatment stages that a fabric may need. The apparel industry eliminates the need to unload printed fabrics and transport them to another finishing station.

Types of Digital Fabric Printing Inks

When printing on synthetic and natural fabrics of varying sorts, such as silk, nylon, cotton, polyester, and various inks, the best printer, retreatments, and fixing methods are required to get the desired results.

Because of the pre-treatment, ink formulation, and post-treatment process, the dye colors can permeate the garments and are more resistant to fading, grime, and several wash cycles.

1. Acid & reactive ink

These two acid and reactive inks are examples of dyes utilized for natural fibers. The hand feels and wash thickness of these dyes are very high quality. Even though these dyes can permeate the fabric rather well, a few steps still need to be taken before they can be used.

These include pre-treating the cloth, heating it, washing it, and steaming it. In the textile industries of Bangladesh, digital printing is accomplished using a reactive dye.

Fabrics prepared with nylon and silk are colored using acid dyes. After the digital printing process is complete, the printed textiles must be cleaned and steamed to remove any residue that may have been left behind.

The acid dye is permanently fixed using heat processing once the print job has been completed, and no transfer paper can remove it.

2. Disperse ink/dye

Banners, soft signs, and sportswear, the fabric often composed of a high percentage of polyester, and spandex, may all be produced using dye sublimation.

This collection has fifteen different colors to choose from. Inks created by sublimation or dispersion may either be transferred directly to the polyester cloth or onto a responsive paper roll.

Printing directly onto polyester and polyester mixes is accomplished via direct-disperse inks. These inks dye the fibers of the fabric. Thus they ultimately become a component of the digital textile printing market. There is a heat treatment performed after this digital printing technology.

3. Pigment ink

Cotton, silk, rayon, cotton/poly mixes, and other natural fabrics are examples of natural and synthetic materials that may be printed using this digital printing technology.

The ink set has a total of eight different colors, including cyan, magenta, yellow, black, gray, orange, violet, and red, to use on the garments.

The pigments in textile pigment inks are held together by binders in ink, so when put into the printer, it allows the pigments to attach to the surface of natural textiles like cotton. A rotating heat calendar permanently attaches the pigment dyes to the fabrics.

The Printing Process

Step 1: Design development

The pattern or motif is digitized first once it is transferred from the paper to the computer. There are two distinct approaches to the creation of designs. First is the digitization process; secondly, photos can be scanned straight if there is no need for changes.

After that, the newly produced file is saved in a format suitable for printing. At this point, any adjustments that need to be made to the color combinations or brightness of the photographs are made.

Step 2: Fabric preparation

Before going through the process, to print the fabric must first be treated. Chemicals, often sizing ingredients, are utilized to cushion the textiles produced at this step. It helps to eliminate the fabric crunches and makes the fabric firmer so that it can be fed through the printing machine more easily. On the flatbed, the padding is completed with the assistance of a scrapper.

Step 3: Printing

Images are printed on the substrate with the assistance of the printer server by making use of the appropriate dye classes, and the printed cloth is then dried appropriately. To begin, the cloth is carefully fixed so there is no looseness and no wrinkles.

After that, the head of the printer is adjusted so that it corresponds to the thickness of the cloth, and then the print is started.

Step 4: Fixation of the dye

During the printing, the dyes stay on the fabric’s surface; they are not permanently attached. If we use the material, the dye will be removed while we use it since it is not permanent. Because of this, it is essential to fix the dyes to ensure they have a good fastness quality.

The steam chamber is where any printed material that has to be fixed will be maintained. The dye molecules are absorbed into the fabric’s fibers from the surface, where they remain forever. The procedure in question is known as the Fixation procedure.

Final step: Washing

The material is then rinsed and dried appropriately after completing the fixing procedure.

Conclusion

The most cutting-edge approach to printing on textiles is digital textile printing, or DTP for short. With this method, we can print on textile material without using any blocks, engraved rollers, or screens, resulting in more prominent pictures.

We can modify the colors within a few seconds if they do not match the example, giving us a great deal of leeway in how we go about our business. When compared to rotary screen printing, the method flow for digital printing on textiles is much more streamlined.

However, the cost of printing is relatively expensive in comparison to other ways of printing on textiles. Therefore, this method is not yet recognized as a viable alternative for manufacturing goods in large quantities.

This method is often used in producing samples for new design concepts and the costume worn by designers. In recent years, however, garment and textile printing facilities have favored having digital textile printing in-house to reduce the sample lead time.